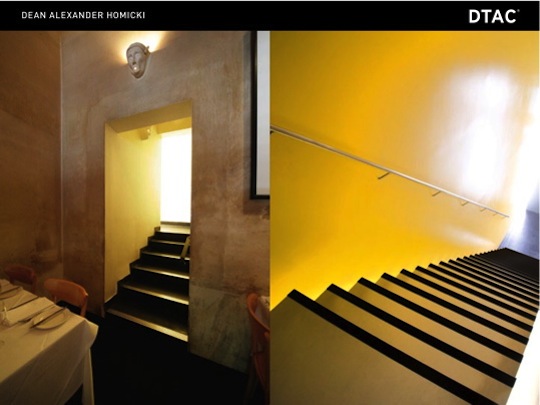

Aluminium has been a material that I have been curious about since I was very young.

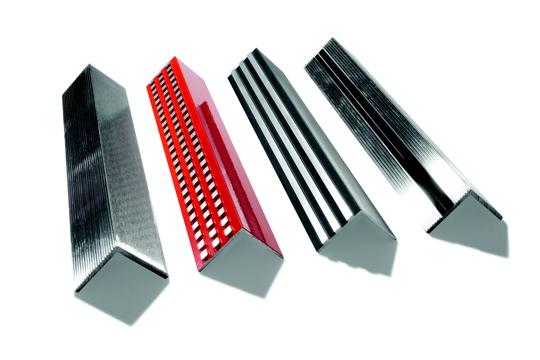

The ‘DTAC EDGING KIT’ – Designed in collaboration with pidgeon.com.au – the ‘bag’ (shown before its unwrapping to the client) – communicate the product as precious and bespoke.

The ‘bag’ (shown before its unwrapped by the client) – communicated the designs as a set of tools or pens; something new draw with rather than just another product – The ‘DTAC EDGING KIT’ – Designed in collaboration with pidgeon.com.au – Dean Homicki for DTAC

As young boy, in my Fathers shed, I was surrounded by numerous pieces of textured and grain embellished aluminium sections. Dad collected de-comissioned military radio and medical equipment. He would pull out the guts of the machines and recycle the aluminium. I would be in the waiting to collect the device’s carcass and investigate the aluminium by continuing the deconstruction of the assembly.

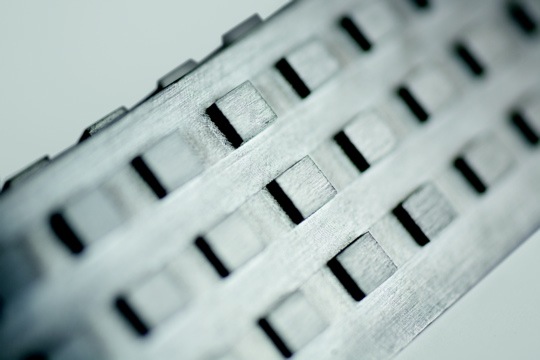

316 Stainless Steel, powder coated milled aluminium. The DTAC EDGING range pushed all the boundaries – Dean Homicki for DTAC – Image David Pidgeon

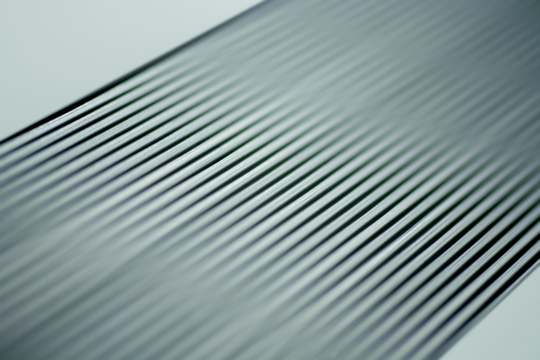

With all this investigation in my father’s shed I grew to understand that aluminium could be harden by a special process know has hard anodising. This technique allowed for the dying of the material to be deeper making colours suitable for horizontal surfaces.

‘Corduroy’ – The first section in the DTAC EDGING Range – These design elements became the basis for the collection – Dean Homicki for DTAC – Image David Pidgeon

In time I discovered the intrinsic possibilities of aluminium’s grain, strength and rigidity. Versatile and malleable, the material could be adapted for many applications and functions permiting decoration of a machined aesthetic.

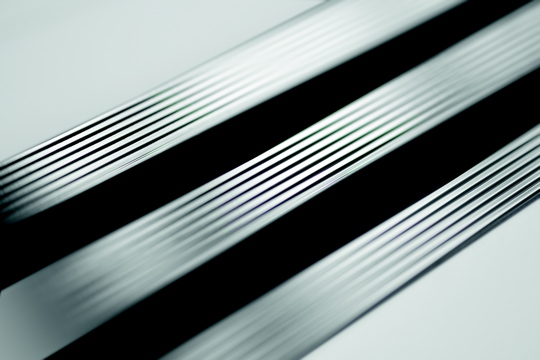

‘Pleat’ – a simple negative and positive (Yin & Yang) relationship – A subtraction of the earlier ‘Corduroy’ design – Dean Homicki for DTAC – Image David Pidgeon

When the opportunity came to design a series of architectural trims for DTAC in Australia, know as DTAC EDGING, the extrusion and hard anodising processes became the natural method and finish.

‘Pinstripe’ – The removal of the ridges from ‘Corduroy’ and ‘Pleat’ – The natural aluminium was revealed after the anodising process by hand finishing – Dean Homicki for DTAC – Image David Pidgeon

Through great tenacity I worked with serval manufactures to communicate my vision and process techniques. While some extrusions where to be simply ‘Anodised’, others would be milled, stamped, subtracted and multiplied.

‘Checker’ – Extruded and Milled Aluminium – A subtracted ‘Pinstripe’ section – Dean Homicki for DTAC – Image David Pidgeon

Some of the designs where also translated into milled 316 stainless steel sections for bespoke architectural applications.

Pushing the limits of the material and available processes, or rather negotiating with manufacturers to create the designs in the manner to which the finished result would transpire, lead to a series of architectural elements that would be very special and precious.

Aluminium is often assumed to be cheep, throw away material and only worthy of soft-drink packages. The transformation of extruded aluminium into the collection of trims known as DTAC EDGING range was truly special in the finale.

This document ‘EVERYTHING TECHNIQUE’ is authored by Dean Homicki. It is free to copy, use and alter providing attribution and reference to deanhomicki.com.au is noted. ’EVERYTHING TECHNIQUE’ – Dean Homicki – Designer, Entrepreneur, Mentor